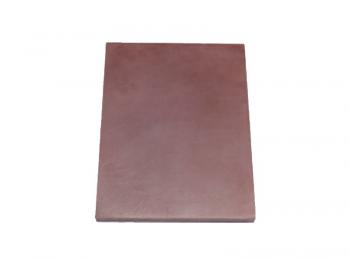

- Thermosetting PI Bar (carbon fiber)

- PEEK, PI because with high wear resistance, high strength, low coefficient of friction, resistance to moderate level of resistance to various chemical corrosion within the automotive liquid medium, has become a manufacturer of high-performance applications in the field of transport products high-gra...

- Inquiry Now

- Share to:

Other Products

New Products

0086-18616115922

0086-18616115922 0086-21-61062069

0086-21-61062069 libing@chinapeek.com

libing@chinapeek.com Room 208A, Shengyu Building, No. 185, Zhangjiang Road, Pudong New Area, Shanghai

Room 208A, Shengyu Building, No. 185, Zhangjiang Road, Pudong New Area, Shanghai

- Hot keywords:

- PEEK Rod,

- PEEK Sheet,

- PEEK Slim Sheet,

- Continuous Extrusion PEEK Sheet

Sitemap Alltag Designed by Zhonghuan Internet CopyRight © 2019-2024 Jiangsu Junhua Special Polymer Materials Co., Ltd All Rights Reserved. 沪ICP备19023756号-2

中文

中文